PRODUCTS

Conductive tape

Protective tape

For chemical etching, photolithography, and plating processes

This is a conductive protective tape used in semiconductor manufacturing processes (chemical etching, photolithography, and plating). This tape is resistant to chemicals used in manufacturing semiconductors (PGME, PGMEA, TMAH, etching liquids, etc.) and protects wafer surfaces from chemical contamination.

Features

- Conductive tape that can be used in chemical etching, photolithography, and plating processes.

- The base material has excellent chemical resistance.

- Even if exposed to chemicals, the tape does not peel off or change in appearance and adhesion.

- The tape is also excellent in heat resistance and can be used in a drying process immediately after chemical treatment.

Specification

- Model number:

- ①STSI-PEN#25 ②STSI-PI#25

- Material:

- ①Conductive PEN ② Conductive PI

- Width:

- 240+/-2mm (For φ200mm) or 330+/-2mm (For φ300mm)

- Length:

- 20m or 80m

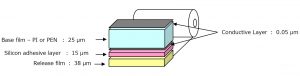

- Base Film Thickness:

- 25+/-2μm

- Total Thickness:

- 40+/-4μm

*The film thickness can be changed.

Configuration image

Physical property

| Unit | STSI-PEN#25 | STSI-PI#25 | Measurement | |

|---|---|---|---|---|

| Surface resistivity | Ω/□ | 1.3×105 | 1.3×105 | High resistivity meter |

| Surface resistivity (Adhesive site) |

Ω/□ | >1.3×1013 | >1.3×1013 | High resistivity meter |

| Decay time | sec | <0.3 | <0.3 | FTM 101C-4046 (23℃×15%RH) |

|

Adhesive strength (vs Glass) |

N/25mm | 0.2 | 0.2 | Peeling Speed : 300mm/min Peeling Angle : 170° |

| Outgassing | μg/g | 34 | 43 | 170℃ 10min. |

| Transparency rate | % | 75 | 47 | JIS K 7105 |

*This data is an actual measurement value, not a guaranteed value.

Chemical property

| Chemical | Surface resistance | Dimension (mm) |

Appearance | Adhesive | ||

|---|---|---|---|---|---|---|

| Before (Ω/□) |

After (Ω/□) |

|||||

| Copper plating liquid | Copper Sulfate | 1.2E+04 | 2.1E+05 | Not change | Not change | Not change |

| Organic Solvent | PGME | 1.2E+04 | 2.1E+06 | Not change | Not change | Not change |

| PGMEA | 1.2E+04 | 1.2E+06 | Not change | Not change | Not change | |

| 1% Sodium carbonate | 1.2E+04 | 1.2E+06 | Not change | Not change | Not change | |

| 3%TMAH liquid | 1.2E+04 | 3.2E+07 | Not change | Not change | Not change | |

| Etching liquid (Cu, pH=1) | 1.2E+04 | 3.9E+05 | Not change | Not change | Not change | |

| Hydrogen peroxide water + Potassium hydroxide (pH=8.5) | 1.2E+04 | 7.7E+11 | Not change | Not change | Not change | |

*This data is an actual measurement value, not a guaranteed value.

![ACHILLES CORPORATION [Achilles]](/asset/images/common/logo-achilles_en.svg)